How world’s first 3D printed cornea restored a 70-yr-old’s vision |

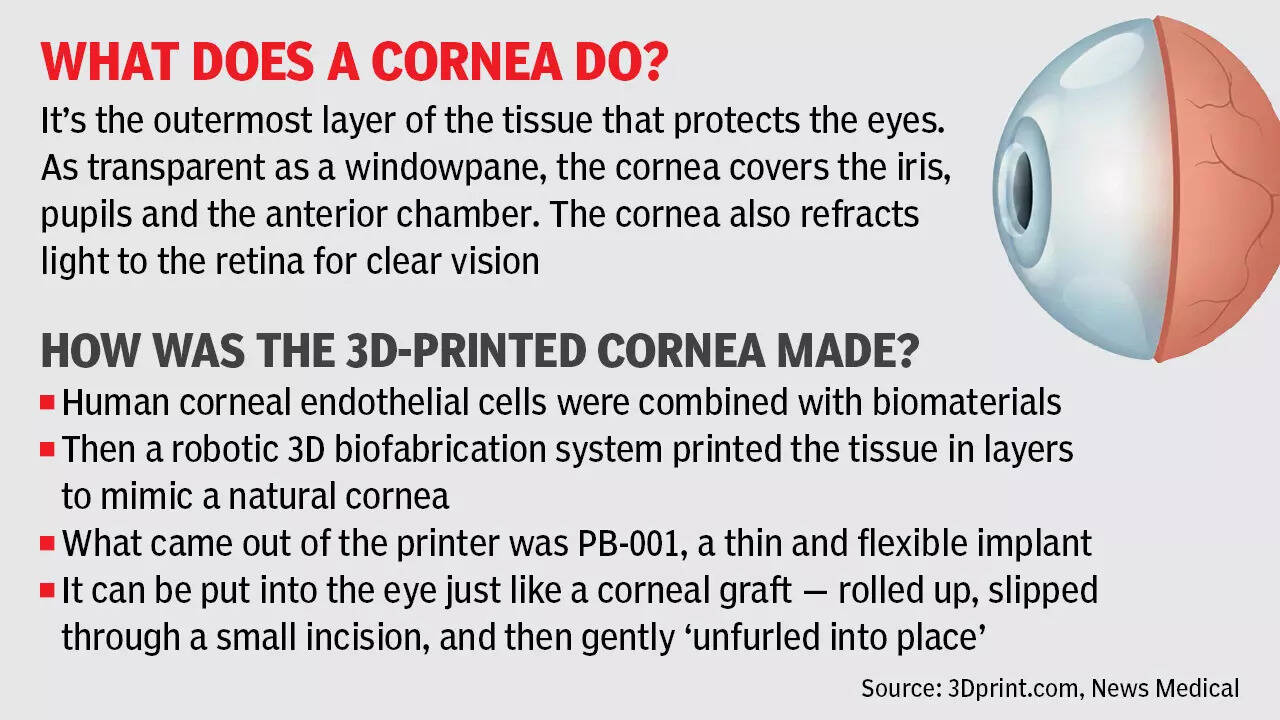

For every 70 people needing corneal implants, there is only one donor cornea available. Now, a 3D printer can make hundreds of perfect copies from that single donor cornea. So far, 3D printing in healthcare has mainly worked for surgical models, prosthetics, and a few customised implants for the skull, hips and teeth. But last month, a 3D-printed cornea (called PB-001) managed to give second sight to a 70-year-old woman blind in one eye, at the Rambam Health Care Campus in Haifa, Israel. This breakthrough holds the promise of a swift solution to the global cornea shortage.“This transplant is a moment of real hope for millions of people waiting for corneal donations,” Aryeh Batt, co-founder and CEO of Israeli biotech firm Precise Bio which printed the cornea, told The Jerusalem Post. “It’s the first time an implant made entirely in a laboratory from human source cells has been successfully used in a human being. This is not only a scientific breakthrough — it’s a historic moment,” he added. The procedure was part of the company’s phase I clinical trial for the 3D-printed implant and the patient has responded favourably so far.

Perfect replica, every single time

Donor corneas are few and far between, pushing waiting periods to years. And even when one is available, their quality varies with the donor’s age and health. Cornea tissue is delicate and has a short shelf life, making preservation and transportation a challenge. But a 3D-printed one could easily get past those limitations. According to 3Dprint.com, bioprinted corneas could soon usher in an era of “ready-to-use implants, frozen and available on demand”. And their quality would be exceptional every single time. It’s a big leap for bioprinting in medical science as previous prints have mostly been structural — small tissues for research purposes, skin patches, and cartilage repairs. But this is the first time that a print has to function effortlessly as part of an organ. And PB-001 seems to have passed that test.

Swiss implants don’t need surgery

Precise Bio is not the only one with a 3D vision. Researchers from the Swiss Federal Laboratories for Materials Science and Technology (Empa) have collaborated with the University of Zurich, the Zurich Veterinary Hospital, and Radbound University in the Netherlands to develop a transparent, self-adhesive 3D-printed cornea implant that doesn’t depend on human tissue donation. “The basis for the implant is a biocompatible hydrogel made of collagen and hyaluronic acid. 3D extrusion bioprinting makes it possible to tailor the implant to the patient’s individual corneal curvature,” Markus Rottmar from Empa told News Medical. Human stem cells will be loaded into the hydrogel at a later stage so the 3D-printed cornea can support tissue regeneration. The best part is that it’s self-adhesive, which means there won’t be any surgical sutures or post-operative complications.

India has tried it on animals

Back in India, researchers from IIT Hyderabad have tested their creation — a 3D printed human cornea using bio-ink developed from donor tissues (with zero animal or synthetic material) — on rabbits successfully. Scientists from South Korea have also managed to bioprint artificial corneas. While global research in ophthalmology is increasingly experimenting with 3D printing technology, it will take a while before that would bear fruit for the masses. But for now, seeing is believing.